Originally published in Concrete Wave Magazine Vol 7 No 2 (Fall 2008)

It was five years ago when we last did a company profile of Comet Skateboards. At the time, they had just co-located their facility with Glissade Snowboards to leverage their manufacturing expertise and solar-powered facility. Since then a lot has happened. Comet’s mission has always been to make light, strong and fast skateboards, affordably, with cutting-edge materials in the most sustainable way possible.

Comet’s president, Jason Salfi, is a longtime skateboarder and has a background in natural resource management. To say he is a committed environmentalist would be an understatement.

“Skateboarding has been responsible for up to 40% of the maple trees harvested annually and millions of tons of VOCs (volatile organic compounds). I saw two great opportunities to help the skateboarding industry have less of an impact: make stronger boards, and do it in partnership with people focused on the future health of communities and environment.”

Comet’s focus has always been on taking pressure off the natural environment while supplying the goods people need to shred. To do this, Jason explains,

“We have worked very hard at abiding by closed-loop (or Cradle to Cradle) design and manufacture principles.”

It was these principles that led Comet to biocomposite engineering in collaboration with e2e Materials in Ithaca, New York. When Jason speaks of affordable, he means much more than how much a board costs the person buying it.

“It means what are the social implications (such as working conditions or health care), environmental implications (such as deforestation or global warming from high VOC lacquers) as well as economy.”

The way Jason views things, cheap products are available because the companies that make them “externalize” the costs of making them.

“Externalizing is the act of placing burden on the environment or society to clean up and/or pay for the ill side effects of producing a -product. When one buys a cheap — say, $20 —blank, there could be the equivalent of $100 in external costs.”

These include things such as landfill remediation, reforestation, worker health care costs etc. When you buy a Comet board for $60, you can trust that you have made an investment in community (a local living economy), a safe environment and a great skateboard. Jason is so committed to the concept of a closed-loop system that if you send Comet your beaten and destroyed skateboard, they will compost it and give you $10 back toward your next board.

“We strive to create a net positive impact on the environment and society as opposed to costs down the road. There will be no cost to society and the planet as there might be with less eco-intelligent products. Our focus is on total responsibility for everything that we make.”

This is a model that has been exemplified in Europe, but Comet is committed to do it in skateboarding and in the youth space.

“How people in their 10s and 20s live their lives will dictate which way this planet goes. That means everything from having a loud voice in present-day politics to everyday buying decisions.”

While spending years of innovating and benchmarking what could be done with epoxy, carbon and fiberglass, Comet had their eye on university and government research labs that were developing high strength-to-weight bio-composites. In 2004, Jason came across a paper written by Dr. Anil Netravali, a professor at Cornell University, where Jason studied natural resource management. For the first time in history, a biodegradable composite based on soy protein and plant fiber was invented that could perform on par with aerospace composites.

In January 2006; Jason was invited to speak at a political activist conference in Washington D.C. Later on that trip he met with Bill Mc-Donough (co-author of “Cradle to Cradle” — a must-read for all aspiring designers and architects) at McDonough’s office in Virginia, and then drove up to Ithaca to see the research he had been tracking first hand. Luckily for him, Dr. Netravali invited Pat Govang, who at the time was in charge of intellectual property (patents and such) owned by Cornell making it into the market place.

Shortly after that meeting, Pat and Anil started e2e Materials, and in late 2007 Comet

“Part of Pat’s focus with e2e Materials was developing regional supply chains,” recalls Jason. “After seeing the west coast BALLE (Business Alliance for Local Living Economies) come to be at the Comet West Coast offices from 2003-2004 with the vision of Don Shaffer, this resonated very well with us.”

In central NY there is a quite a bit of farmland. In the next year e2e / Comet will be sourcing all of its soy protein for resin from the by-product/waste stream of biodiesel production. Through bio-fuels, biocomposites and a skateboard company working together regionally, Comet envisions activating the economy and farmland to produce solutions for the future. By relocating to the East Coast, Comet cut the distance that their woods, glues and coatings traveled to less than 500 miles.

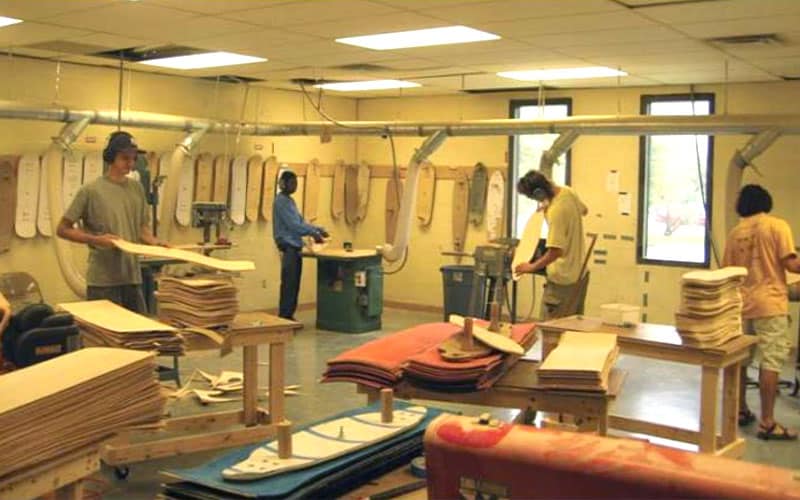

With e2e, they can rapidly prototype new formulations of the resin and work on new applications for the product. The goal is to eliminate the concept of waste altogether and create high-performance products in a perpetual biological cycle that feeds the earth or the next generation of products. The factory in Ithaca is a basic wood shop with the e2e Materials high-tech lab attached. This is where e2e makes the resin. They have about 10 employees laminating, cutting and decorating, tons of materials until they are under your feet in the form of a skateboard.

Along with their own boards, they are making boards for five other companies of all shapes and sizes.

“Comet East smells sweet like a farm,” Jason says. “My daughter can play in the wood chips, and we compost our scrap. We are a biodynamic-organic skateboard-making machine.”

Comet views making skateboards as an extension of a farm and the agricultural base that has made the USA and Canada strong. In that regard they have been rethinking the way they sell skateboards.

“We are creating the analog to the CSA (Community Supported Agriculture) in skateboarding,” Jason says.

A CSA operates by members of a community near and far joining a farm and getting shares of what is grown. For example, Comet paid $500 for their CSA for eight months of fresh produce and can barely keep up with eating it. They are doing the same in skateboarding through the Internet. Comet Skateboards team members Justin Bryant, Blake Smith and Nick Lee have designed and programmed a social forum for skaters to congregate online. The website will offer free membership that allows people to meet and find like-minded people online to hang with in the real world, plus donation memberships that get people all their favorite skateboarding gear, music downloads and so on in abundance. The amount ‘- one pays for how much gear they get is possible because of committed support and a predictable cash flow for Comet. A paid membership is completely ethical because it is optional, Jason says.

As he sees it, “The majority of people who would accept our offer would be skaters who are loyal to our company and our vision of skating. They are helping us, and we do whatever possible to hook them up — be that better board and gear deals, free stuff, custom graphics, custom boards…”

Comet’s vision is not to eliminate the local skateboard shop but to work with it in a different way. In the case of Comet, they make a fun and interesting community platform for skaters of all disciplines (street, pool, vert, longboarding, downhill, sliding) to post pictures of themselves, write blogs about their favorite skate spots and decks and create friendships with other skaters. It is just about creating connections without the drama. Both the Comet website and the team’s community-based website have the same intentions: to help grow the skating scene by getting people excited about it.

“Our job is to connect all skaters so they can spread the knowledge and stoke of skating to others, while always keeping an open door to all new skaters. The Internet is the perfect mode to do this. Take MySpace and Facebook, for example. People like the idea of having their own ‘personal space’ online that they can share with others. But Facebook and MySpace don’t have any one specific topic and have too many users that can’t connect on a common ground. We have that common ground for our users: skating. This will not only benefit the skaters by giving them a fun personal space to meet other people and get hooked up with good skate deals, but it will also benefit the skating community as a whole by inviting more skaters to come out and ride,” Jason says.

Comet believes this will be informative to people who want to buy their boards too. Things are mostly heard and told by word of mouth (or blog — same thing, basically). Information is spread skater to skater, not as much by the companies as it has been in the past.

“Skaters want to hear it from skaters. We will be trying to skip the company website description-of-a-board BS and allow you to ask someone who’s got the one you got your eye on,” Jason says.

I asked Jason about the cool factor of “being green,” and he was pretty forthright in his response.

“Over the last two years everything green has really taken off. It has always been codbin some circles to have high regard for the environment, but for the most part, if you uttered the word ‘eco,’ you were pegged as a hippie. We would talk about eco-initiatives we were making since 1998, when we started, and shops would say ‘Whatever — how much?”

Nowadays, Comet is getting calls from individuals, shops and distributors from all over based on the merits of their “eco-grooviness.” For Jason, it all fits together seamlessly.

“Our stuff is tech, and the boards are built to shred. Now, if you are not thinking about your impacts on the planet, you are in denial. With the eco-revolution kicking into full gear, mainstream press has been all over us.”

He’s not kidding about the press being all over Comet. In late 2006, Jason wound up on the cover of Inc. Magazine. I asked him how that came about.

“In 2004 we got asked to film for Current TV and Treehugger and got coverage in a couple of newspapers and magazines. The media was super-hot on the green and social responsibility tip. The whole triple-bottom-line (measuring social, environmental and economic impact) business practice thing was and still is in its infancy, and we were really viewed as the real deal because we have been living it before it was trendy.”

Inc. featured Comet on the cover of a magazine that read “Do Good, Get Rich.”

“I reckon we are the ‘Do Good’ part,” remarks Jason.

Since that cover, they have been featured on Sundance, History Channel, Discovery Channel (twice) and NBC’s Today Show. Jason appreciates having the opportunity to tell the Comet story because it is pretty easy to replicate.

“I can see a whole group of young people and entrepreneurs following dreams just like we have. It is cool that skating is having this impact,” he says.

If there is one thing Jason would like to tell the rest of the industry, it would be the idea of focusing on the concept of collaboration.

“I definitely want to give a big shout out to Frank Scura of ASEC (Action Sports Environmental Coalition). He has helped provide a blueprint for a united industry on a sustainable platform. If you are making stuff, check out ASEC [us-asec.org], join, and donate some cash to that cause — the value for the services far outweighs the investment.”