This article will cover the standard sizes, materials, and head types.

Skateboard Hardware Sizes

Nut Sizes

There are three different nut sizes used for skateboards/longboards. Ensure all nuts are nyloc to prevent loosening.

- 10-32 (Baseplates)

- 5/16″ (Wheels)

- 3/8″ (Kingpin)

The baseplate nuts are the tiniest and mount the trucks to the deck. The wheel nuts are the mid-sized nuts that secure the wheels onto the truck axles. The kingpin nuts are the largest ones that screw onto the kingpin, securing the bushings.

Screw Sizes

The standard screw size is 10-32.

10 refers to the standardized sizing by ANSI B1, and 32 refers to the thread count. There are 32 threads per inch. Most setups will use bolt sizes in the 1-2″ range. If you use thicker riser pads, you might go beyond 2″.

How to choose the right size

Trying to figure out what size screws you need?

The average 7-ply maple deck is 1/2″ thick, truck baseplates are an additional 1/8″, and the nuts are about 1/4″. So combined, the average setup is about 7/8″.

Typically you want about 1/8″ of the bolt to stick out so the nut’s nylon ring can properly lock to the threads.

Let’s make it easy; we’ll round it up to an inch. So all you have to do is add 1″ + your riser pad size to get the proper bolt size.

It’s always best to measure your setup, but this should give you a rough idea.

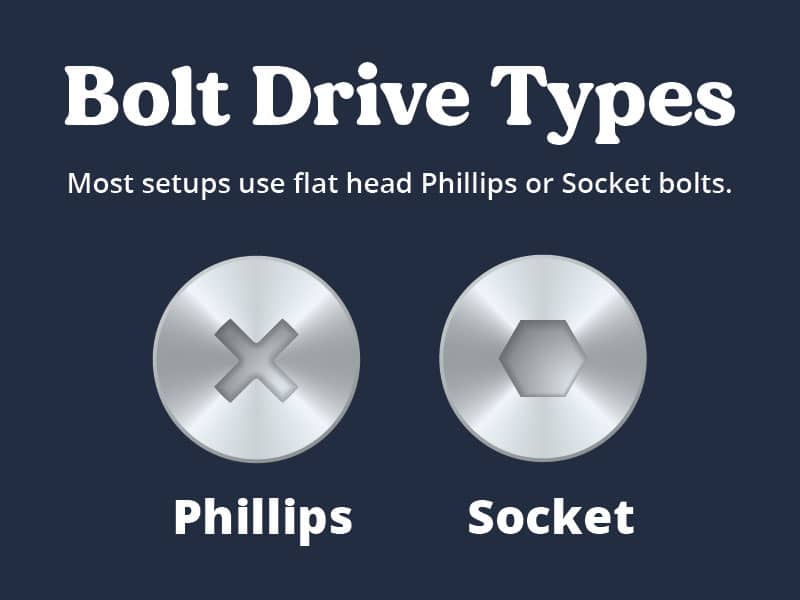

Screw Drive Types

The drive type refers to the pattern used on the head of the screw. It determines what type of tool you’ll use.

For example, you would use a Phillips screwdriver on a Phillips bolt. And an allen/hex key for socket bolts.

Depending on the pattern, it’ll offer less or more torque.

So, which should you choose?

Well, like most of skateboarding, it’s subjective. It’s not the end of the world if you pick one over the other.

Phillips Pros & Cons

- Easier to find a phillips screwdriver

- Higher chance of stripping

- Less torque

Socket Pros & Cons

- Harder to find an allen key

- Lower chance of stripping

- More torque

If you live in the USA, Phillips head is most likely the best option because it’s easier to find a Phillips screwdriver. If your deck is drilled correctly, you won’t need a lot of torque to tighten skate hardware.

If you’re someone who somehow continuously strips hardware, then go for socket bolts.

Screw Head Types

The most common head types are countersink and button. Countersink heads sit flush while button heads are exposed. Choosing one depends on your riding style/ how your deck is drilled.

Most street decks are predrilled for countersink bolts.

Buttons vs Pan Heads

If you go for buttons over countersink, you should consider pan heads.

Pan heads are similar in shape to buttons but have a lower/wider head profile. However, they can be trickier to find, especially in zinc-plated steel.

If you plan on doing ollies/fliptricks, you’ll want countersink bolts, so they’re flush. Buttons will get in the way if you go to flick your foot.

But if you’re doing a riding style where you don’t need your bolts to sit flush, then it doesn’t matter. If you ride barefoot, you probably won’t want button heads.

Material

Should you use 18-8 stainless steel or zinc-plated steel?

One of the main benefits of stainless steel is it’s less likely to rust.

So, why wouldn’t you use stainless steel?

Well, first it’s more expensive. But it’s not a big difference when buying only eight bolts.

The main issue with stainless steel is that it’s more prone to locking up since it’s softer. It’s common for stainless steel nuts to lock up, and the only way to get them off is to cut the bolt.

When you add the chance of the griptape adhesive mixing with the sand grit and sticking to your bolts, the chances of your hardware seizing up are even more significant.

This is not to say don’t use stainless steel because if the most important thing for you is its corrosion properties, then you can rub a little soap on the bolt threads. This will combat any nuts seizing up. (Thanks to Gavin for suggesting this technique!)

For most people, using zinc-plated steel bolts with zinc-plated nuts is the way to go. It’ll save you many headaches if you often switch out your setup. Go for stainless steel if you often ride in wet conditions.

Bottom Line

For 90% of skaters, go for zinc-plated hardware. If you need that extra protection against rust, go for stainless steel. It just requires a little more care.

It all depends on your riding environment and style.